Metal decks have become an essential component of modern construction since they are durable, versatile and efficient flooring and roofing solutions. When selecting a metal deck manufacturer, it’s crucial to consider various factors to ensure that you choose the best supplier for your specific needs.

Below we explore the fundamentals of metal decking and its three main types. We’ll also discuss how to pick a dependable metal deck manufacturer that you can trust.

What is Metal Deck?

There are three main types of metal decks: metal roof, steel form and composite form. Each deck type offers different benefits and is suitable for specific applications.

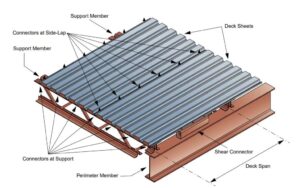

Metal Roof Deck

Metal roof decking is an engineered structural panel that serves as a foundational base to bear the load of rooftop systems. It has become commonplace in commercial and multi-story buildings and provides support for both dead loads (such as rigid board insulation or built-up roofing) and live loads, such as people walking on roofs. Metal roof decking is available in depths of 1.5 -inch Type B and 3-inch Type N, as well as other options.

Steel Form Deck

Steel form deck provides a permanent form for your concrete flooring slabs and eliminates the need for temporary wooden forms in order to make installation fast, easy and efficient. With the proper design, you can rest assured that shoring the slab won’t be necessary during construction. Steel form deck offers lateral rigidity without binding to the slab, but does not add strength to the concrete.

Common depths are 9/16-inch steel form and 1.5-inch steel form. These types of metal panels can be used for an array of applications, such as stairways, foundations or shallow mezzanine builds.

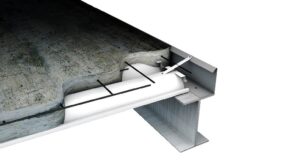

Composite Form Deck

Composite decks are easily distinguished from steel form decks due to the presence of embossments. The repeating indentations inside the flutes of the profile provide a locking mechanism between metal and concrete that results in an end product that is more robust than concrete alone. Composite form deck has become vital for construction projects like:

- Commercial buildings

- Bridges

- Porches

- Parking garages

- Self-storage facilities

- Traditional slab infills

Composite decking is offered in 1.5-inch, 2-inch and 3-inch deep panels.

How to Select a Metal Deck Manufacturer

There are numerous metal deck manufacturers available to choose from, so deciding who to use for your project may seem overwhelming. To refine your search, take the following factors into account:

Competitive Pricing

When it comes to the quality of materials, don’t be tempted by low-cost options. Yes, price is essential, but so is material excellence. There’s no need to compromise. The best manufacturer will offer both outstanding products and competitive pricing. In the long run, this will save you money and give you peace of mind in your purchase decisions.

Turnaround Time and Delivery

Consider the manufacturer’s availability and lead times, as this will impact your project timeline.

Wide Variety of In-stock Products

A manufacturer with a large inventory and quick turnaround time will help ensure that your project stays on schedule.

Technical Support and Customer Service

A quality metal deck manufacturer should offer excellent customer service and technical support throughout the project. This includes assisting with product selection, installation and any potential issues that may arise during the construction process.

Ensuring Quality and Consistency

With a forward-thinking, cooperative attitude towards supplier quality, metal deck manufacturers can ensure top-notch products every step of the way by closely tracking and directing the entire production process. This guarantees increased customer satisfaction and ultimately contributes to the success of the organization.

Customization Options

Every construction project has unique requirements, so it’s essential to choose a manufacturer that offers customization options for their metal deck panels. This includes the ability to produce custom lengths, profiles and finishes that can meet your specific project needs.

Metal Deck Certifications

When picking a supplier, there are numerous certifications to keep in mind to ensure you receive the highest-quality decking:

SDI Certified

Choose a metal deck manufacturer that adheres to industry standards and holds relevant certifications, such as SDI certification. Since 1939, the Steel Deck Institute (SDI) has been working tirelessly to establish a reliable system of standards and regulations for steel deck engineering, design, production and application. SDI members are mainly manufacturers of superior-grade steel products that act as effective forms or reinforcements in concrete roofs and floors.

FM Approved

FM is an insurance carrier that insures buildings for natural disasters, such as earthquakes, tornadoes and hurricanes. To control their losses and to limit premiums, there are FM-specific design criteria that must be met during design and construction that are more conservative than standard building codes. This is based on their research for higher load conditions, especially wind loads, fire and the behavior it has on the buildings it insures. Choose a metal deck manufacturer that adheres to FM acceptance criteria.

UL Approved

Underwriter’s Laboratory (UL) requirements are related to steel decking for fire and wind in commercial structures. For example, if a UL fire rating is specified on the contract drawings, then the EOR has selected materials in an assembly that comply with the specified fire resistance rating.

The Underwriter’s Laboratory also tests roof assemblies for uplift. Most deck types can be engineered and manufactured to follow (UL) deck constructions, which are rated for wind uplift Class 90.

Where applicable, your steel deck supplier must be able to supply UL-approved materials and be competent at reviewing any Underwriter’s Laboratory (UL) requirements related to steel decking.

ICC-ES Reports

ICC-ES reports are third-party certifications occasionally seen on contract documents. While they are slightly a dying requirement today, it’s worth understanding when selecting a deck manufacturer. Years ago when metal decking was the wild west, many engineers required them because there were no standards for metal decking. This was especially prevalent on the West Coast in seismic zones.

However, with the Steel Deck Institute, ANSI standards are now part of the building code — if a metal deck manufacturer adheres to the SDI standards, which all SDI members do, they are already in compliance with the building code. Thus, you don’t need an ICCES report but some manufacturers still carry this additional certification as EORs may request this certification.

LEED Certification

Sustainability is an important issue within the construction industry, and your metal deck manufacturer should incorporate sustainable practices into their production and shipping processes. LEED certification letters are available upon request and this requirement should be communicated to your supplier before placing an order.

O’Donnell Metal Deck is the Premier Distributor of Metal Deck in the U.S.

O’Donnell Metal Deck products are unparalleled in the industry and for more than 35 years, our company has been at its forefront. We have offices all over the U.S., which makes us easily accessible to our customers from coast-to-coast.

Whether you need pre-planned custom orders or immediate stock from our vast inventory, contact us today to get started!