Metal decking, sometimes referred to as steel decking, is a cold-formed corrugated metal sheeting that is formed into specific patterns of flutes and ridges. The deck is supported by joists or beams and supplies structural support for the insulating membrane of a roof. It may also be used in floor systems.

There are three main types of steel deck — metal roof deck, composite decking and steel form decking. Metal roof decking is widely used for commercial and industrial structures. It works with a variety of roof styles including pitched, flat and arched roofs.

Composite decking can serve as a working platform during construction or as a permanent form for wet concrete. Steel form decking is designed to be a permanent steel form for concrete floor slabs.

Fabrication Process

Metal decking is available in a range of depths, widths and gauges. The strength and stiffness of the deck panels is the result of the shape of the ribs and the gauge. At O’Donnell Metal Deck, we stock 1.5-inch Type B, F and A roof decks as well as 3-inch N decks. We carry all gauges and finishes.

To manufacture metal decking, a bill of materials or (BOM) is uploaded/sent to the deck line, and the correct roll formers which create the deck profile are set on the machine.

Loading the Coil

Steel coils of the proper gauge are then loaded onto a unicoiler machine which unwinds the coil into a flat sheet that can be fed or inserted into the start of the roll-forming machine. The steel sheet is then pulled through a series of roll-forming machines where it is made into the appropriate type of metal deck.

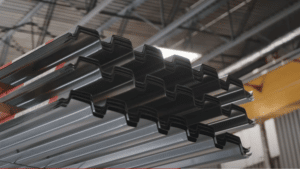

Roll Forming

As the sheet steel is fed into the roll former, if the profile contains composite embossments they are typically rolled into the flat sheet steel before the profile is formed.

Once the steel has passed the optional deck embossing stage, the Roll A series of roll formers incrementally bend the flat sheet of steel into the finished corrugated profile by being passed through consecutive sets of steel rollers. Each set of rollers bends incremental parts of the profile to slowly mold the cold steel into the desired metal decking profile. Unlike other metal manufacturing methods, roll forming is inherently flexible, which allows the deck line to add secondary processes to the metal deck production process.

This means that while the steel coil is being rolled into the metal deck, the addition or option of the different side laps can occur while being integrated into a single production line.

Roll-forming metal deck increases the efficiency of steel deck production by eliminating unnecessary handling as well as the need for additional equipment.

Cutting the Decking

The deck is then cut by a shear or, commonly, a flying shear. The flying shear is used for cutting metal decks continuously at the same speed at which the deck line is rolling metal decking. This helps to ensure that the steel deck manufacturing process is not interrupted and is maximizing the productivity of roll forming or deck lines.

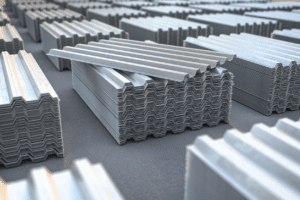

Bundling and Banding Metal Deck

The steel deck is stacked after being cut to length, and upon completing the bundle (in accordance with the BOM), the deck is bundled with steel bands and dunnage.

It’s important to consider the construction load requirements for framing when bundles or steel decks will be applied over steel frames on a job site. Deck bundles can weigh several thousand pounds, so it is important to request specific deck bundle weights as required. If not specifically dictated, a maximum of 4,000 pounds for deck bundle is common.

If the bundle weight can be heavier or must be lighter, this information must be given to the deck manufacturer before production so that it can be coordinated. The steel erector, deck supplier and steel deck purchaser all need to be aware of the sizes or lengths of the deck, and the weights of the deck that are to be delivered to a job site. Once a deck bundle is manufactured, a label is applied to the steel deck.

Standard deck bundles information typically provides some or all of the below information:

- Bundle Mark or Number

- Bundle Weight (lbs.)

- Deck Supplier’s Project #

- Customer and Project Name or PO#

- Steel Deck Type, Gauge, and Finish

- Material BOM included in bundle or pieces and lengths included

- Special Notes or Marks

On occasion, a request can be made that certifications such as those required by (FM) Factory Mutual or UL (Underwriters Laboratories) are applied to the bundle. Again, if these special markings or labels are required for your project, this must be communicated in advance to production and packaging prior to the steel deck production scheduling for coordination.

Now that the bundles are made and the labels completed, the decking is ready to be loaded.

Loading Metal Deck After Bundling

The deck manufacturer will prepare to load trucks once the last bundle of a deck BOM has finished manufacturing. They may schedule the deck bundling if requested so that it will be delivered in a particular (or previously agreed upon) order and be unloaded and hoisted in a particular sequence.

All job conditions that will affect shipping weight restrictions, staging, special strapping, blocking and tarping should be discussed as early as possible and ahead of production and fabrication so that the carrier or shipper can coordinate. Trucks are then loaded:

- When possible, the deck bundles should be placed against the trailer or truck bulkhead to prevent forward movement in case of a hard stop. Due to the required load distribution, this may not always be possible.

- Typically, the longest bundles of the deck will be loaded on the bed of the truck at the bottom in order to balance the load.

- When stacking multiple deck bundles, they are separated with wood dunnage so that lifting slings or forks can safely be inserted between bundles for offloading the decking.

Once the truck has been loaded, the manufacturing process is complete.

Metal Deck Finishes

The following types of finishes are commonly used for steel decking.

Galvanized

Galvanizing is the most popular finish and it does not require a finished coat of paint. Galvanizing is the process of applying a thin coating of zinc onto the steel to protect the metal from corrosion. It is recommended in high moisture or corrosive environments.

Galvanized and Prime Painted

Galvanized decking is given a primer coat on one or both sides. The deck can then be given an architectural paint finish in the field that will most likely be a special order.

Uncoated Steel

Uncoated steel is not galvanized but is painted with a primer on both sides. It is also referred to as “cold-rolled” painted. This should be considered a temporary coating and not a finished product.

Trust an Industry Leader

O’Donnell Metal Deck is one of the premier metal deck suppliers in the country. With over 35 years of experience in the industry, we provide our customers with dependable and reliable service.

Contact our experts today to request an estimate for your project.