Metal decking is a popular choice in construction because of its strength, durability and versatility. It is also becoming more in demand for its eco-friendliness and efficiency, which has led to the increasing popularity of these systems worldwide. This article discusses the three main types of metal decks: roof decks, steel form decks and steel composite decks.

Metal Deck Overview

Metal deck systems act as vital structural supports for a range of floor and roof systems.

Typically crafted from steel, these systems are available in an assortment of profiles, thicknesses and finishes to suit the distinct demands of different construction projects.

Owing to their exceptional strength-to-weight ratio, resistance to corrosion and easy installation process, metal deck systems are a top choice for both commercial and residential endeavors.

Metal Deck Categories

There are three primary categories of metal deck systems: roof deck, steel form deck and steel composite deck. Each type has its specific applications and advantages, and their span capabilities depend on factors such as the type of deck, gauge and back-span condition.

Roof Deck

O’Donnell Metal Deck – Metal Roof Deck Products

Roof decks are designed to support various roofing materials, insulation and weatherproofing systems. They act as both a structural component and a diaphragm by providing lateral support to the building’s framing system. Roof decks are available in a variety of profiles, such as corrugated, ribbed or cellular for flexibility in design and application.

Applications for roof decks include commercial buildings, warehouses, schools and residential projects. The strength and lightweight nature of roof decks make them ideal for creating flat or sloping roofs, and they can accommodate various roofing systems, such as built-up, single-ply or metal roofing.

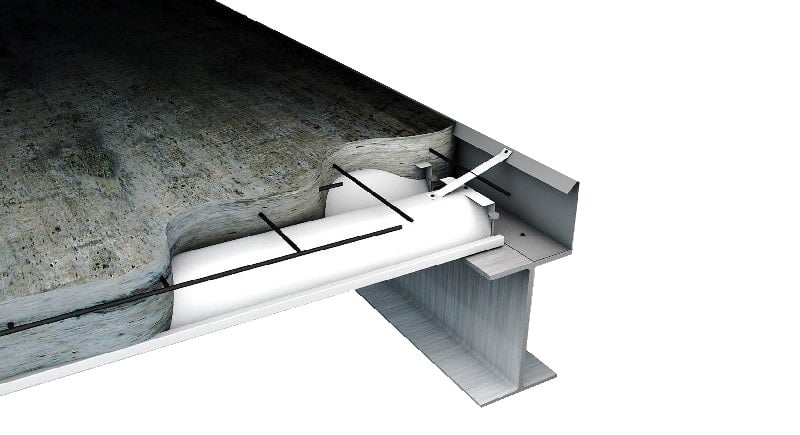

Steel Form Deck

O’Donnell Metal Deck – Steel Form Decking

Steel form decks are used as stay-in-place formwork for concrete slabs. They are installed directly on top of structural steel or concrete framing, in order to provide a base for pouring concrete floors or roofs. Steel form decks come in various profiles, such as fluted, dovetail or deep-rib, with diverse design and structural options.

Applications for steel form decks include office buildings, parking garages, multi-story residential buildings and industrial facilities. The use of steel form decks can speed up construction times and reduce the need for additional formwork or shoring, ultimately leading to cost savings.

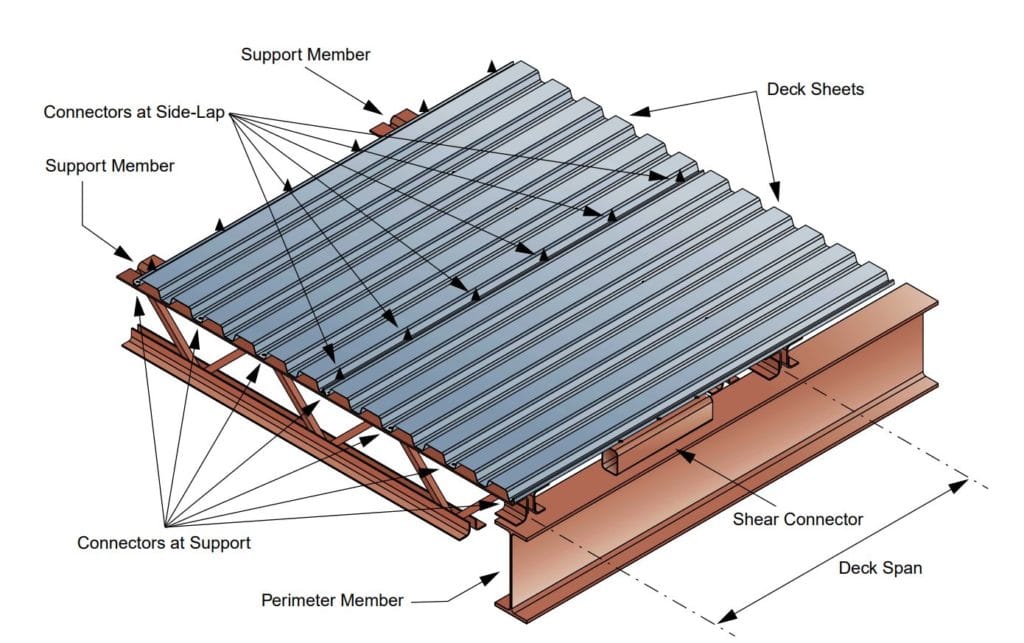

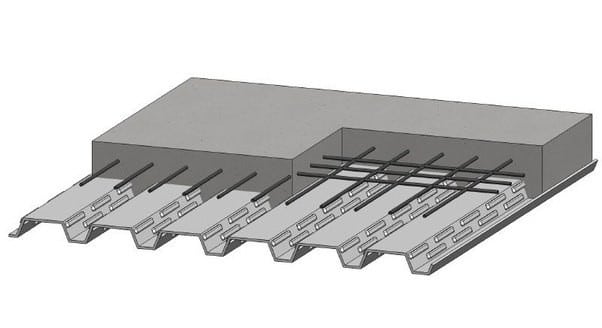

Steel Composite Deck

O’Donnell Metal Deck – Steel Composite Metal Decking

Steel composite decks are a combination of steel form decks and reinforced concrete slabs. They are designed to act compositely with the concrete to create a strong, rigid floor system that can span greater distances than non-composite systems. Steel composite decks are available in various profiles, such as fluted or cellular, to suit different project requirements.

Applications for steel composite decks include high-rise buildings, hospitals, airports and sports arenas. The composite action between the steel deck and concrete provides an increased load-carrying capacity and reduces the need for additional structural support for a more efficient and economical construction process.

Metal Deck Span Capabilities

The span of a metal deck refers to the distance it can support between two or more supporting members without compromising its structural integrity. The single span is the weakest condition while a triple span would produce the strongest. In addition, the span capabilities of metal decks depend on several factors, including the type of deck, gauge and back-span condition, and the KSI rating. This rating refers to the hardness of the steel. In general, metal decks can span distances ranging from 1 foot to 11 feet, depending on the specific deck type and configuration.

The maximum span allowed also takes into account the total weight a metal deck panel can handle and the amount of deflection that weight will produce under general conditions.

Roof Deck Span

The span of a roof deck is primarily determined by its profile, gauge and the roofing material it supports. Additionally, the spacing of the supporting members, such as joists or beams, can significantly impact the span capabilities of a roof deck. In general, roof decks with deeper profiles and thicker gauges can span greater distances.

It is essential to consider factors such as live loads, dead loads, wind loads and snow loads when determining the appropriate roof deck span for a specific project. The most common roof deck panel, the “B” type, applied in a single layer will generally span 6 feet 10 inches for 22 gauge material and up to 13 feet 11 inches for 16 gauge material.

These figures are dependent upon numerous factors and need to be verified before installing the product. Always verify span allowances with the supplier or the designated engineer on the project.*

Steel Form Deck Span

The span of a steel form deck is influenced by factors such as the deck profile, gauge and the weight of the concrete it supports. Deeper profiles and thicker gauges generally allow for greater spans. The spacing of the supporting members and the design loads, including the wet concrete weight and construction loads, should be considered when determining the appropriate steel form deck span.

Properly designing the steel form deck span can help minimize deflection and ensure a more efficient construction process.

The 1-inch steel form deck is very popular in construction projects, and using a single layer of form deck with a total lightweight concrete depth of 3 inches, the span is generally 4 feet for 26 gauge, and up to 6 feet 8 inches for 20 gauge material.*

Steel Composite Deck Span

The span of a steel composite deck depends on the composite action between the steel deck and the concrete slab, which significantly increases the system’s load-carrying capacity. Factors that affect the span capabilities of a steel composite deck include the deck profile, gauge, concrete thickness and the type and amount of reinforcement used in the slab. Composite decks can generally span greater distances than non-composite systems due to their increased rigidity and strength.

Designing a steel composite deck requires careful consideration of the deck’s span, load requirements and supporting member spacing to ensure optimal performance and cost-efficiency.

The 2-inch composite floor deck panel, applied in a single layer with a total lightweight concrete depth of 4 inches, will generally span 7 feet 9 inches for 22 gauge material and up to 12 feet 3 inches for 16 gauge material.*

Selecting the Right Metal Deck System

Selecting the appropriate metal deck system for your project requires careful evaluation of factors such as span requirements, load capacities and project-specific constraints.

Partnering with an experienced metal deck provider like O’Donnell Metal Deck can help guide you through the decision-making process and help ensure that you choose the right metal deck system for your project.

Choose O’Donnell Metal Deck for a Durable and Versatile Solution to Your Metal Decking Needs

O’Donnell Metal Deck has 35 years of industry experience, and we can assist you in selecting from numerous top-tier metal deck systems tailored to your needs. Utilizing our design and engineering prowess, we can deliver a decking solution that is not only robust but also versatile enough to cater to your particular requirements.

Our knowledgeable team is here to help you understand the technical aspects of metal decking and support you throughout the decision-making process, to help ensure that you select the ideal metal deck system and accessories for your project.

Reach out to us today to discover how we can help fulfill your metal decking requirements.