Are you working on a commercial, industrial or residential project that requires the use of concrete and metal decking? If so, you may be wondering which type of concrete is the right choice to ensure strength and durability. The truth is, selecting the wrong type of concrete can result in project failure, which is why it’s crucial to make an informed decision.

Luckily, the experts here at O’Donnell Metal Deck have put together an educational article to help you make the right choice. In this article, we’ll explore the use of concrete over metal decking and its applications in construction projects. We’ll also dive into the different types of concrete available, their advantages, and their applications. Additionally, we’ll cover the differences between metal roof deck, steel form deck, and composite deck panels. By the end of this article, you’ll be equipped with the knowledge needed to make an educated decision for your project. So, let’s dive in!

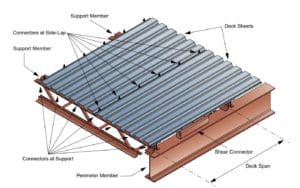

What is Metal Decking?

First things first — what is metal decking? A perfect solution for both commercial and industrial construction projects, metal decking can be employed to create effective base structures for built-up roofing or concrete floor slabs.

The metal panels provide dependable reinforcement to ensure your structures are both strong and secure. Metal floor decking is a useful solution for many commercial and industrial construction projects, as it can be shaped into various widths, depths and gauges to match the specific requirements of each job.

Types of Metal Decks

Roof Deck

When it comes to commercial roofing, metal roof decks are the ideal structural base — they are installed over bar joists or steel beams so that users can build a reliable working platform that accommodates insulation and weatherproofing. Moreover, a steel roof deck serves as the perfect shield from wind, and it can also meet code requirements for providing fire resistance in a UL-approved roofing system.

Steel Form Deck

Steel form decking is an essential component of many construction projects, both commercial and residential. Not only does it provide a cost-effective option for supporting concrete slabs during the curing process, but it also comes in various depths to meet different applications.

Using a steel form deck in your construction projects can help reduce the cost of post and shoring, as well as labor prices. Additionally, it is suitable for building floor foundations, stairways and mezzanines. Steel form deck panels are available from 9/16 inches to 1.5 inches in depth.

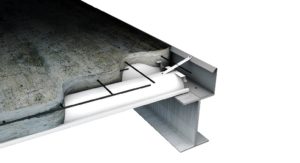

Composite Deck

A composite steel deck is an essential component for many projects, as it can support wet concrete and its own weight across a span. It also supports the weight of construction activity occurring on top of it.

After curing, the embossments on the decking interact with the concrete, rebar and slab design to form a composite section that keeps everything in place beneath any applied loads. Composite deck panels are manufactured from 1.5 inches to 3.0 inches in depth.

Types of Concrete for Metal Decks

There are many types of concrete used in commercial, industrial and residential construction. To achieve maximum strength and durability you’ll want to use the right concrete type and mix. Two of the more popular mixes are structural and non-structural.

Non-Structural Concrete

Non-structural concrete is used in applications that require limited compressions or temporary loading, such as parking lots, sidewalks and handicap ramps. It is a convenient option for these types of projects due to its low strength requirements and the more relaxed rules governing its composition.

Insulating Concrete

Non-structural insulating concrete is a lightweight material that weighs only 28 pounds per cubic foot and is specially formulated by combining concrete and insulation elements such as vermiculite or Zonocel. It’s most often applied to metal roof decks for additional thermal protection.

Before rigid board insulation (RBI) came onto the scene, insulating concrete was solely used as an insulation product. Today, insulating concrete is combined with rigid board insulation for greater effectiveness and performance when constructing a roofing system. After the metal deck is in place, a layer of insulating concrete will be poured over it.

A layer of RBI will be applied followed by another layer of insulating concrete. The concrete helps hold the RBI in place.

Structural Concrete

Structural concrete is a particular blend of aggregates, cement and water that has been formulated to resist pressures up to 4,000 lb/in2 or more, as in the case of high-performance concrete.

How Structural Concrete is Categorized

When using concrete for structural applications, there are two main options: normal weight and lightweight. Normal weight concrete relies on natural crushed stone as the coarse aggregate while lightweight concrete utilizes a more refined clay, shale or slate material heated in a rotary kiln to temperatures around 2,000°F.

Normal Weight Structural Concrete

Ordinary concrete tends to be substantially heavier at 140-150 lb/ft³ due to the presence of natural stone aggregate.

Lightweight Structural Concrete

Structural lightweight concrete has a much lower density than regular weight concrete — from 90 to 115 lb/ft³ compared to 140 to 150 lb/ft³ respectively. This makes it an ideal solution for modern buildings that require slimmer foundations and makes the project easier and more cost-effective to construct.

Typical Applications for Various Concrete Mixes

Lightweight Concrete

Lightweight concrete is the ideal choice for creating multi-layered flooring on already existing structures since it helps to reduce the risk of collapse. This makes it ideal for use in bridges, decks, girders, piers and precast buildings with reduced density.

Normal Weight Concrete

This type of mixture is commonly used in residential or light commercial construction when pouring slabs on grade. In this application, there is no advantage to using a lightweight mixture as the earth is supporting the weight of the floor rather than other structural elements above grade.

O’Donnell Metal Deck Carries Premium Roof Deck, Form Metal and Composite Decking

For more than 30 years, O’Donnell Metal Deck has been providing the construction industry with top-notch metal roof decking, steel form decking, and composite deck panels. Our commitment to excellence is seen in our record — 15,000+ completed projects using our premier materials.

For any organization, from private businesses to government agencies, our team of specialists can offer you seasoned product expertise, speedy shipping and continuing support.

Contact us today and let us assist you with your next project!