What is Steel Form Decking?

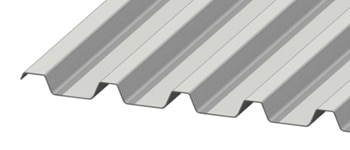

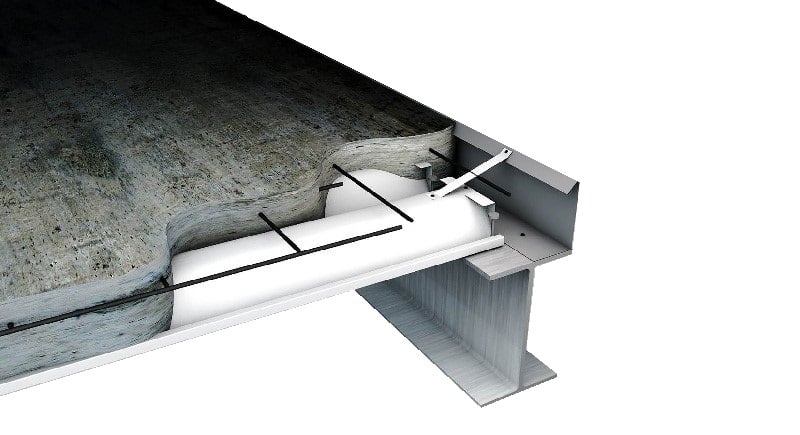

Steel form deck are used extensively in the commercial and residential construction of many concrete floor applications. Available in a variety of depths suitable for these numerous applications, steel form decking for concrete is an economical way to support concrete slabs during the curing process. The deeper the decking, the stronger the decking is and the wider the spacing of the structural members can be. The use of specifying form deck in construction can help eliminate the need for expensive temporary post and shoring, including labor. The available profiles in multiple depths allow for many design options for the spacing of structural support members.

Metal Form Deck FAQs:

What is Form Deck Used For?

"O’Donnell Metal Deck form deck or often referred to as non-composite Deck is used in a variety of applications such as foundations for floors, stairways, or mezzanines. Form deck acts as a metal pan or permanent form to support concrete until it is cured. Form decking provides required lateral stability in slab design.

How Far Can Form Decking Span?

Every project has unique design criteria as determine by the EOR (engineer of record) and the EOR is responsible for specifying the form deck that will meet this design criteria. Each type of form deck differs in terms of the weight of the concrete that it can support. The uniform load being supported generally is not a factor when selecting a non-composite deck because it is only being used to form concrete and not designed to provide positive reinforcement.

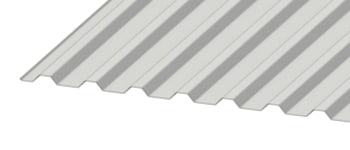

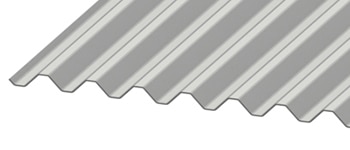

What Are The Dimensions Of Form Deck?

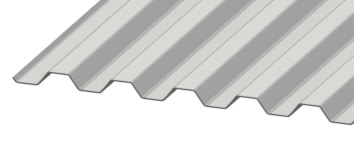

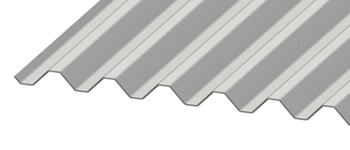

Metal form deck is made by rolling steel coil into various shapes called profiles. Thus, there are different types of roof decking that have unique dimensions and thus properties. The different metal form deck profiles allow specifying engineers to design for specific requirements.

How Wide is Steel Form Deck?

Each type of form deck differs in terms of the tooling and coil blank that is required to create the pan. Generally speaking form decking varies in cover width by profile between 27", 28", 30", 35, and 36" cover widths.

Types of Steel Form Deck

Steel Form deck is designed to serve as a permanent steel form for concrete floor slabs. Temporary wood forming is eliminated, making steel form decks fast, easy and efficient.

Steel form decking or non-composite deck acts as a steel form for concrete until it cures. Proper design can determine which form deck types will eliminate the need for any shoring of the slab during the construction phase. These steel pans provide lateral stability but do not engage with the slab. Therefore when selecting a steel form deck pan, the uniform load normally is not a factor since the slab is not designed to provide positive reinforcement.

This deck type can be used in such a variety of ways and is used primarily in floor seen in stairways, foundations or shallow mezzanine designs.

What Gauge is Form Deck?

The metal deck gauge is a unit of measurement that refers to the thickness of the steel. The higher the gauge number the thinner the steel. The lower the gauge number the thicker or heavier the steel is.

Example 1:

20ga 9/16 form deck is thicker, and therefore stronger & heavier than 26ga 9/16 form deck

Example 2:

22ga 9/16 deck is thinner, and therefore lighter & weaker than 20ga 9/16 form deck

What Gauge Form Deck Do I Need?

The (EOR) or Engineer of Record should be dictating the form deck gauge requirement for the specific job requirements. However, typically the form deck gauge will depends on the below factors:

- Load capacities and/Concrete slab capacities

- Span capabilities of the deck during or after construction

- Diaphragm shear values

Below is a chart of thicknesses measured in inches for commonly used gauges for steel form decking.

Most Common Form Deck Gauges |

|||

| Type | Gauge | Thickness / (in.") | (lbs. / ft2) |

| 9/16 | 20 (ga) | .0598 | 1.90 |

| 22 (ga) | .0474 | 1.55 | |

| 24 (ga) | .0358 | 1.25 | |

| 26 (ga) | .0295 | 0.95 | |

| Type | Gauge | Thickness / (in.") | (lbs. / ft2) |

| 7/8 | 20 (ga) | .0598 | 1.91 |

| 22 (ga) | .0474 | 1.63 | |

| 24 (ga) | .0358 | 1.31 | |

| 26 (ga) | .0295 | 0.93 |

| Type | Gauge | Thickness / (in.") | (lbs. / ft2) |

| 1.0 | 20 (ga) | .0598 | 1.95 |

| 22 (ga) | .0474 | 1.65 | |

| 24 (ga) | .0358 | 1.31 | |

| 26 (ga) | .0295 | 0.93 |

| Type | Gauge | Thickness / (in.") | (lbs. / ft2) |

| 1 5/16 | 20 (ga) | .0598 | 1.59 |

| 22 (ga) | .0474 | 1.37 | |

| 24 (ga) | .0358 | 1.13 | |

| 26 (ga) | .0295 | 1.11 |

| Type | Gauge | Thickness / (in.") | (lbs. / ft2) |

| 1.5 | 16 (ga) | .0598 | 3.35 |

| 18 (ga) | .0474 | 2.65 | |

| 20 (ga) | .0358 | 2.05 | |

| 22 (ga) | .0295 | 1.65 |

Form Decking Finishes

The finish of the material used for steel deck is most commonly one of the below:

Galvanized deck exposed to ordinary atmospheric conditions does not need to be field painted for structural purposes. Often times, painting galvanized deck is desired for aesthetic purposes. It’s important to note that proper steps are taken to ensure proper adhesion to galvanized coils if a primer is not applied at the factory. Various oils or chemicals used to prolong the life of the coil may impact paints ability to adhere properly.

Prime Painted is applied to provide provisional protection for short periods of exposure. Therefore, uncoated steel with paint should only be considered a temporary coating not a finished product. A final coating is recommended as handling, transportation and jobsite conditions are expected to impact the quality of the finish.

Since bonding action is not necessary for non-composite form decks, they may be painted on one or both sides. Form decks that are non-structural after the overlying concrete slab is cured may be made from steel that is uncoated on both sides. Uncoated steel is sometimes referred to as “black,” which does not imply that it is painted with black-colored paint

| Form Deck | Function | Finish | ASTM | Comment |

| Non-composite steel form deck for reinforced slab | 1. Galvanized

2. Uncoated or Bare 3. Painted with a shop coat of primer paint |

A1008 | The finish of a non-composite form deck shall be as specified by the designer and be suitable for the environment of the structure | |

| For any permanent load carrying function | Galvanized | A653 |